Sodium Carboxymethyl Cellulose is a kind of high molecular polymer and cellulose ether. It can be widely used in Oil Drilling, Mining, Food, Detergent, Ceramic and Paper making industries. And sometimes, we also focus on molecular weight of CMC in pharmaceutical applications. Do you know the relationship between D.S and molecular weight ? It all depends on the DP=Degree of Polymerization and D.S=Degree of Substitution of Sodium CMC. Let’s introduce them briefly here.

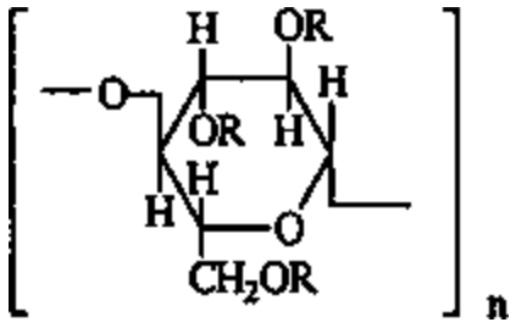

1. Sodium CMC structure formula: R = H, CH2COONa or CH2COOH

2. General chemical formula:

[C6H7O2(OH)x(OCH2COONa)y]n

Remark:

n: the DP=Degree of Polymerization of CMC

x=1.5 to 2.8 y=0.2 to 1.5 x+y=3 y=DS=Degree of Substitution

3. Formula weight:

When y=0.2, molecular weight:178.14

When y=1.5, molecular weight:282.18

Macromolecules=17000(n about 100)

4. Normally, we mainly focus on viscosity, purity and D.S when choosing the suitable type CMC, because these three items much influence its application. However, sometime, we also need to consider the Degree of polymer, especially in R&D step and pharmaceutical industries, eg: eye drop, injection drugs.

Besides, different viscosity is made from different raw materials(refined cotton and wooden fiber). Ultra low viscosity CMC is made from wooden fiber, medium viscosity CMC is made from mixed refine and wooden fiber and high viscosity CMC is made from refine cotton.

Various types of Sodium CMC(granular CMC), powder CMC, dispersing grade CMC, ultra low viscosity CMC can be provided by us. If you need more information and technology support about our Sodium CMC, please contact SINOCMC freely.

SINOCMC Team