Wahsing powder is widely used in laundry washing and cleaning industries. And the international market has huge demand for washing powder. We would like to introduce washing powder production process briefly now.

1. Main Raw Materials and Approximately Dosage:

(1). Sodium Carboxymethyl Cellulose is the basic ingredient of powder detergent, especially non phosphorus powder. It has the characteristics of the colloid; It can effectively prevent washes from becoming contaminated after being washed by synthetic detergent. When it used in detergent powder, it can stabilize the bubble and protect our hands. Dosage: 0.5%-5%.

(2). Sodium Sulfate: it has strong alkaline in detergent that can inhibit the oxidation of organic materials. It also has antioxidant and antibacterial effects which can effectively prevent clothing mold and prevent bacteria growth. Besides, it can also increase the consistency of the detergent and improve the washing effect. Dosage: 40%-50%.

(3). 4A-Zeolite, it has excellent decontamination effect and can soften the water and remove impurities. Dosage: 5%-10%.

(4). Sodium Hydroxide, it has strong alkaline in detergent that can inhibit the oxidation of organic materials. Besides, it can also adjust pH value during washing test and can help remove the dirt easily. Dosage: 10%-20%.

(5). Surfactants: SDS=Sodium Dodecyl Sulfate, SDBS=Sodium Dodecyl Benzene Sulfonate and perfume etc. Dosage: 5%-10%.

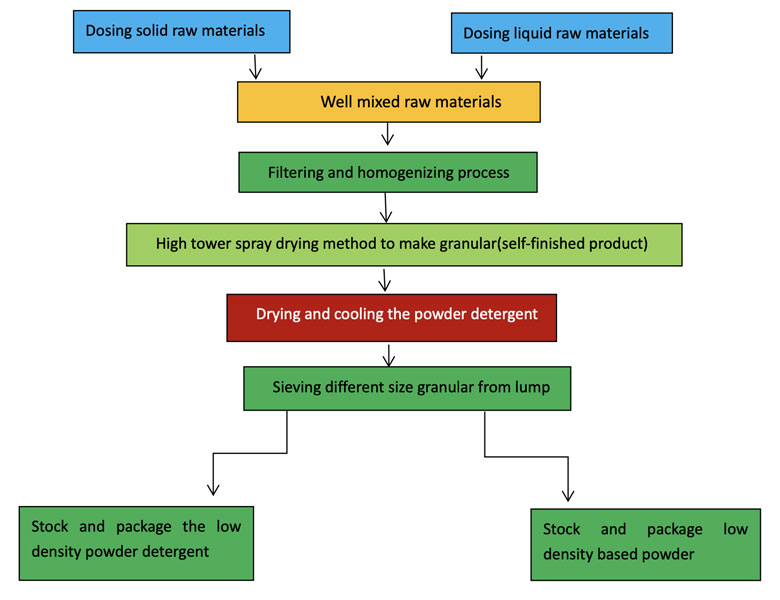

2. Production Process: High Tower Spray Drying method to make washing powder

Besides, Sodium CMC can be also used in liquid detergent, detergent paste, soap and other personal care products. If you have any demand for detergent grade Sodium CMC, please don’t hesitate to conact SINOCMC.

SINOCMC Team