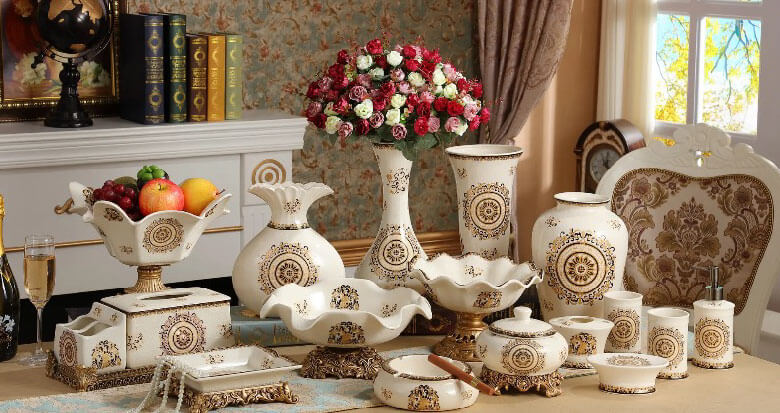

With the increase of people’s pursuit of quality of life and beauty, ceramic products as a combination of functionality and beauty is becoming more and more people’s choice. It has frequently appeared in the scene of daily life, such as pot, bowl, plate, spoon and some other tableware in the kitchen, pleasing tea cup and teapot, various types of decorations in the living room, etc. Our product, ceramic grade CMC, is widely used as an important additive in the ceramic industry, which can be added as excipient, plasticizer and reinforcer of billet. It plays the role of strengthening, retaining water, bonding, suspension and dilution in the production process of ceramic blank body, glaze paste and glaze silkscreen printing, especially the lack of high-quality clay resources today. CMC as a strengthening agent of the body can effectively solve this problem.

In the production of ceramic green body, CMC can effectively strengthen the support and stability of green body by forming firm network and hydration film, making it easier to plastic. In the production of glaze slurry, the addition of CMC can control the rheology, improve the adhesion ability of the glaze, prevent the particle from settling and delamination, and prevent the glaze surface from streaking, etc., so as to achieve a smooth glaze effect. In glaze printing, the acid, alkali and salt resistance property of CMC ensures that it dissolves quickly in printing glaze, reduces cleaning times and color difference, and effectively ensures the stability of printing glaze in the storage stage.

CMC is white powder, easy to dissolve in water, non-toxic and tasteless, with good dispersion, significant enhancement effect, no negative impact on the final performance of ceramic products even in high temperature environment, especially easy to operate, no need to change the original production technology.

The amount of CMC used in body and glaze must be different, which need to be confirmed according to formulations and experiments.

SINOCMC Team