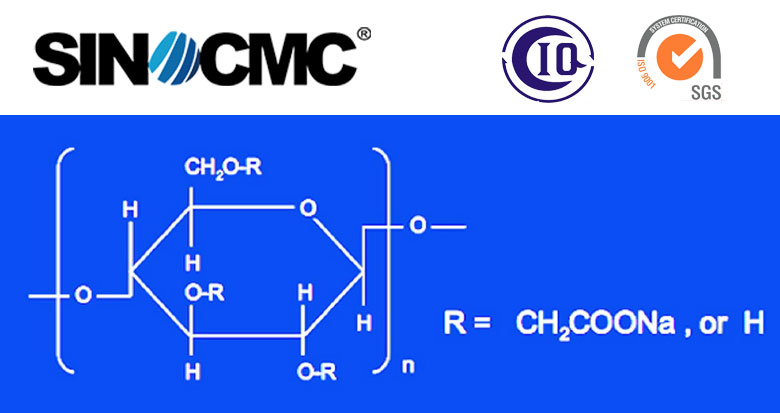

Sodium CMC is a kind of Cellulose Ether which is made from natural cellulose(refine cotton or wooden fiber). It’s good emulsifier, thickener and suspension agent that can be used in food, detergent, ceramic, paper making, oil drilling and mining industries. And Sodium CMC solubility is a very important characteristic during application. Let’s introduce different Sodium CMC solubility in different solution, temperature and mixed materials briefly.

1. Sodium CMC dissolved in aqueous solution

Normally, we test Sodium CMC viscosity in different aqueous solution, such as: 1%solution, 2% solution, 4% solution and 10% solution etc. If you have any request, we can also test based on your request. And normally, different percentage solution won’t influence Sodium CMC solubility rate.

2. Sodium CMC dissolved in different temperature solution

We test Sodium CMC viscosity at 25℃ in laboratory. It needs to stir for 2hours before testing. The dissolved solubility rate is higher if the temperature is higher(25℃ to 60℃) and pH is at 6-9.

3. Add some reagent before dissolving

It will be helpful if we can add some methanol, ethyl alcohol and sodium bicarbonate before dissolving. Besides, you can also mix all solid materials together before dissolving and then pour it into solvent slowly and stir fast. For example: Sodium CMC can be mixed with Xanthan Gum, Guar Gum, Pectin, Soda Ash and STTP etc.

4. Particle Size and instant Sodium CMC

Granular Sodium CMC dissolves fast compared with powder CMC. The particle diameter is big, so it’s not easy to gather together. We can also add some accelerator reagent into Sodium CMC, but it can be only suitable for industrial Sodium CMC not purified grade CMC with purity more than 99.5%.

Instant Sodium CMC, powder and granular Sodium CMC all can be provided by SINOCMC. If you have any question about Sodium CMC, please contact SINOCMC freely.

SINOCMC Team